CAM1250-H Large Negative Pressure Air Grinding Machine

Air classification grinder

——Sodium bicarbonate grinding in flue gas deacidification process

Hazardous waste treatment, steel plant coke oven, thermal power generation, municipal waste, sludge incineration, non-metallic ore burning, ceramic industry, glass manufacturing

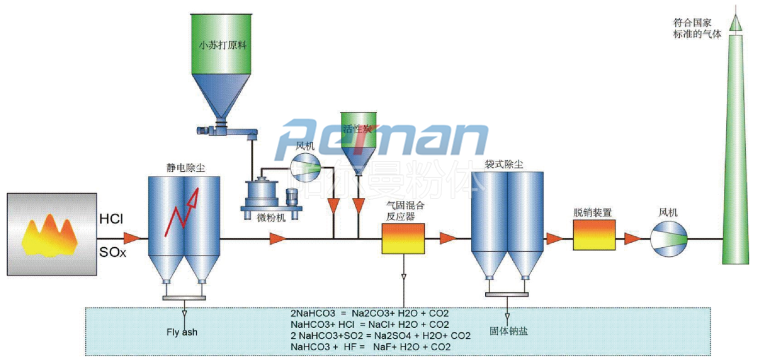

With the increasingly strict requirements of environmental regulations, the dry deacidification principle of baking soda developed by Parman in combination with advanced processes in Europe and America has been increasingly applied. Dry adsorption using sodium bicarbonate as adsorbent to remove various pollutants contained in flue gas. Its purification effect can be compared with other known methods, such as spray adsorption with lime milk as adsorbent. Dry flue gas purification can not only be used in coal-fired power plants, hazardous waste treatment, municipal waste or alternative fuel incineration plants, but also widely used in industrial furnaces in industries such as glass, cement, and metallurgy. The use of dry flue gas purification can economically remove gases containing acidic substances, such as SO2, HCI, etc., and meet the national standard for flue gas emissions.

The flue gas contains a large amount of acidic gases. After extensive data and experiments, it has been found that only when sodium bicarbonate (baking soda, NaHCO3) is small enough to react efficiently with the acidic components in the flue gas. It removes acidic pollutants from flue gas through chemical adsorption, and can also remove some inorganic and organic trace substances through physical adsorption. This process directly sprays sodium bicarbonate fine powder into high-temperature flue gas. Sodium bicarbonate decomposes at high temperatures to produce sodium carbonate Na2CO3, H2O, and CO2.

In general, the flue gas temperature is between 140 and 250 ° C. Due to the high activity of sodium bicarbonate adsorbents, a slight excess of sodium bicarbonate (with a stoichiometric factor between 1.1 and 1.3) is usually sufficient.

The particle requirements are related to the composition of the flue gas, and the required particle size for the removal of SO2 and HCl may vary. Due to transportation and storage reasons, sodium bicarbonate raw materials are usually coarse particles (with a d50 value of approximately 200 microns). To achieve high reaction activity, the adsorbent must have a large specific surface area. Therefore, before injecting into the flue gas pipeline, sodium bicarbonate must be ground to a certain fineness. For example, to remove SO2, the fineness of sodium bicarbonate must reach d90<20 μ m. And removing HCl only requires d90<35 μ m. If the system operation is correct, more than 95% of SO2 can be removed; The removal rate of HCl can even reach 99%. In order to maintain the required fineness of sodium bicarbonate in long-term operation, an air grinder is usually used for grinding, and the adsorbent is transported by gas transportation and directly introduced into the flue gas pipeline through multiple nozzles to ensure uniform dispersion in the pipeline. This equipment is designed to be simple and durable, and its investment and operating costs are lower compared to other flue gas purification methods.

The sodium bicarbonate grinding process will be the core process of this technology.

CAM-H negative pressure air grinder

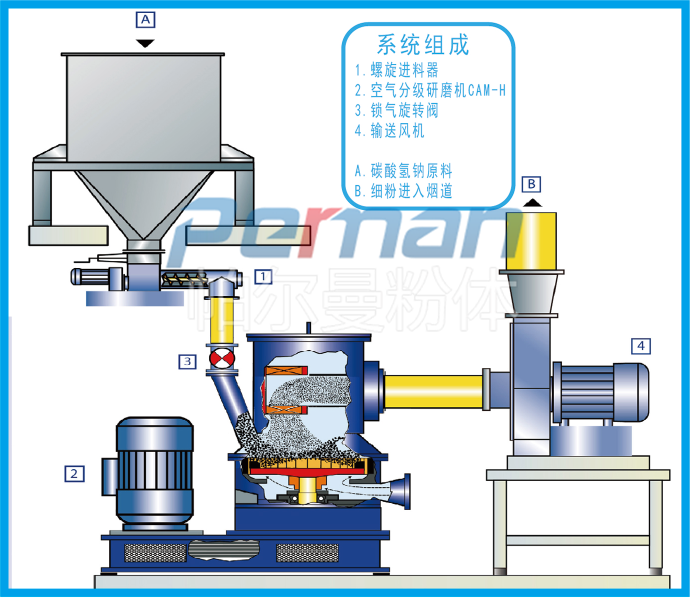

In this process, sodium bicarbonate is quantitatively supplied to the downstream CAM-H series air grinder through a variable frequency screw conveyor from the raw material warehouse. The required amount of adsorbent can be calculated from the trend curve of pollutant concentration before and after desulfurization. Install a rotary valve between the screw conveyor and the grinder to isolate the airflow and prevent it from affecting the quantitative feeding of the screw conveyor. After grinding sodium bicarbonate in a graded mill, the fine powder is transported to the flue gas pipeline by a material conveying fan.

operational principle

Sodium bicarbonate is uniformly fed into the CAM air classification mill through a weight loss spiral feeding system, where it collides, rubs, and shears with the high-speed rotating grinding block and gear ring under various forces. After crushing, it enters the classification area with the airflow, and qualified materials enter the flue through the classification wheel for reaction. Coarse materials fall into the crushing area and continue to be crushed. The size of the particles can be adjusted by adjusting the speed of the classification wheel.

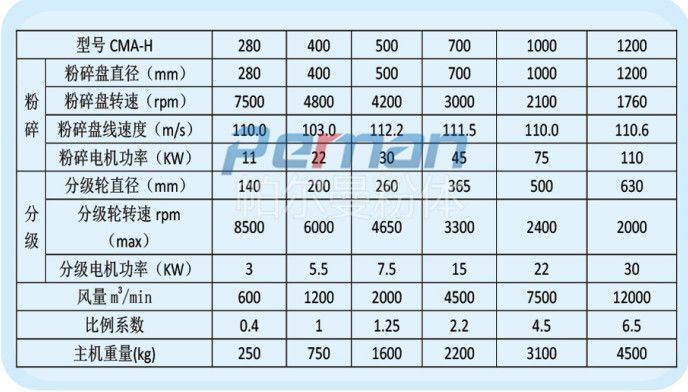

technical parameter