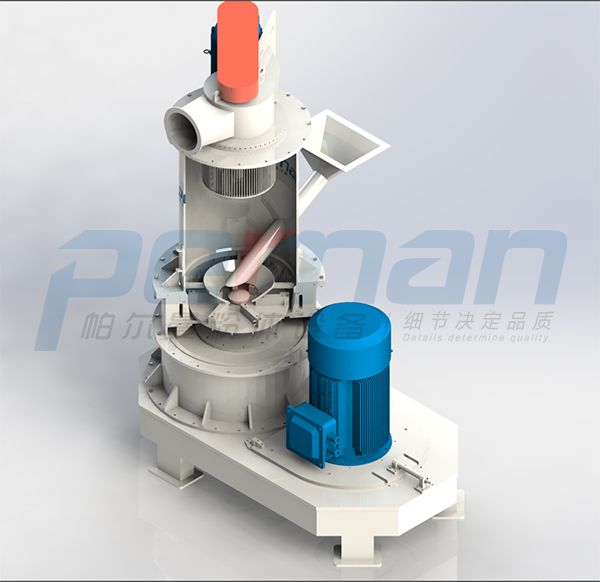

CAM-C Horizontal Cracking Carbon Black Deep Processing Special Equipment

Working principle:

The materials are uniformly fed into the crushing chamber by the feeding system and are subjected to strong impact from the high-speed rotating grinding disc. At the same time, they are subjected to centrifugal force and collide with the grinding ring, and are subjected to various comprehensive forces such as shear, friction, and collision, causing the materials to be crushed. The crushed materials move to the classification area with the airflow, and are separated from the coarse and fine materials through the frequency conversion adjustable classification wheel. Products that meet the fineness requirements enter the cyclone collector and dust collector with the airflow for collection, and the coarse materials return to the classification area for secondary crushing.

Product advantages:

Integrated design of crushing and grading, achieving ideal product particle size by adjusting the grading wheels.

Compact structure, small footprint, low installed power, wide application range, and high cost-effectiveness.

According to the characteristics of the material, the crushing components can be flexibly changed (rod shape, hammer head, tooth shape, etc.) to obtain different crushing forces and improve crushing efficiency.

Suitable for product crushing between D50 2 and 75um.

process flow

1. Cracking: Using continuous cracking equipment under high temperature and catalyst action, crude carbon black is cracked in negative pressure and some corresponding ash is neutralized.

2. Iron removal: The automatic high magnetic iron remover further separates the steel wires mixed in the carbon black.

3. Ultra fine grinding: The mechanical ultra-fine crushing and grading machine grinds the coarse carbon black to a fineness of d100<45um that meets the requirements of the filler, and the residue on the 325 mesh sieve is less than 0.001%. Or according to downstream application requirements, produce ultra-fine carbon black powder with 600 mesh, 800 mesh, 1500 mesh, and 2000 mesh.

4. Activation modification: The coating continuous modification machine modifies the surface of carbon black through coupling agents, increasing compatibility with polymers and improving affinity between the two

5. Granulation: The continuous wet granulation machine produces carbon black particles from fine carbon black powder by adding a certain amount of water and adhesive, which does not affect market application. It optimizes packaging technology, reduces packaging and transportation costs, and improves downstream operating environment.

6. Drying: The amount of water added during the drying and granulation process.

7. Transportation and packaging: Implement full process automation for transportation and warehousing according to production process requirements; Customized implementation of 20-25kg small bag packaging and 750-1000kg ton bag packaging based on terminal applications.